In case you are wondering, I.M. Hammered Brewing is:

Mark -- Head brewer and drinker (brewer of over 65 batches of extract and all grain brews, drinker of many thousands of bottles and pints of beer), CEO and President of the finest Nano-brewery I know of, head bottle washer, and sanitation engineer

Liz -- Vice President in charge of bar decorating, keeping me from becoming too fanatical in my brewing habits, and is also known as "she who must be obeyed"

Michael -- Brewhouse assistant, equipment consultant, Chief IT Geek and self-appointed Official Beer Taster (great work if you can get it)

Schpankie -- Newest convert from fizzy yellow water to finely crafted beers and ales, adds little value to the brewhouse, but we like him anyway

Scooter -- The gas man (and I mean that in the kindest of ways) bringing propane and co2 when needed, also has keen interest in the brewing process

Knuckle Jefe -- Newest convert to brewing (has four batches under his belt), has began a start up nano-brewery in Kentucky known as "Double-Wide Brewing" with the catchy slogan of "double wide beers at single wide prices". Boy has a brilliant future in marketing. IMH is helping with equipment in the start up. We all work for beer, then again, why wouldn't we.

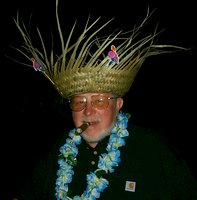

Parrot Pete, aka, Pappa Draft

-- Bar designer, humidor raider, label celebrity, and Just because he should have been on the list the whole time.

-- Bar designer, humidor raider, label celebrity, and Just because he should have been on the list the whole time.

We hope to make this site fun and informative and look for outside input, or inside output, whatever works.

Sunday, October 26, 2003

CHECK IT OUT!

CHECK IT OUT!

The Photo Gallery has been updated. The all Grain system had it's first brew and boy, was it a blast! check out the photos of the setup. Feel free to email the Brewer with any questions you may have. Enjoy!

-Michael, Chief Geek and Number 1 brew assistant (aka. the guy who cleans everything up ;) )

Thursday, October 02, 2003